| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : LiFA

Model Number : CCMT09T308-HM

Certification : ISO9001-2008

Place of Origin : zhuzhou China

MOQ : 10PCS

Price : Negociated

Payment Terms : T/T,Western union

Supply Ability : 100000pcs/month

Delivery Time : 15days

Packaging Details : 10PCS in a plastic box

Material : Tungsten Carbide

Grade : YBC251/YBC252

Coating : CVD

Color : Gold & Black

Usage : External Turning Inserts

Chipbreaker : HM

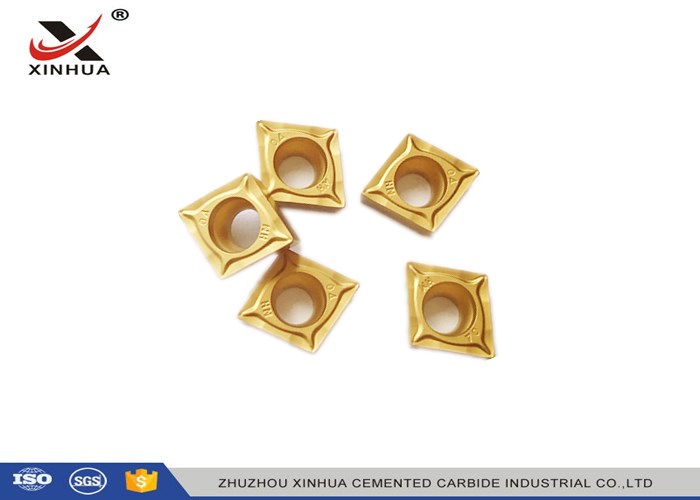

Carbide Turning Insert CCMT09T308-HM for Steel and Cast Iron

Application:

CVD coated carbide grade, wear-resistance materials coated on the gradient sintered substrate which has both good hardness, toughness. Can bear high temperatures. For steel and steel castings finishing to roughing processing,Continue cutting to light interrupted cutting. Machining of gray and ductile iron at low to medium cutting speed. For hard materials continuous cutting and light interrupted cutting from finishing to roughing. Wet and dry processing

| The Chipbreaker Instruction of Carbide Indexable CNC Turning Inserts | |

| DF | Chip-breaker with special angle design can make cut easy,control chip and get good surface quality. |

| DM | Widely used chip-breaker is used for semi-finishing and finishing machining steel and stainless steel. |

| DR | Special chip-breaker with high toughness cutting edge can reduce cutting force. |

| PM | With stronger cutting edge,it is better for intermittent cutting than -DM,with widely cutting zone of P type material. |

| HF | With sharp cutting edge,used for finishing machining inner hole,fine finishing surface can be got with small feed rate. |

| HM | With sharp wave cutting edge to reduce cutting force,it is the first choice for semi-finishing machining of inner holes and can make chip flow smoothly. |

| HR | With tough cutting edge,used for roughing/machining of inner hole and intermittent machining workpiece with irregular surface. |

| LH | Mainly recommended for finish turning,Typical parts: Ordinary aluminum parts. |

Description:

>> Material : P15, K15

>> Coating Type : CVD

>> Processing category : Finishing

>> Density : 13.7g/cm3

>> Hardness : 91.4HRA

>> Bending Strength : 2000N/mm2

>> Cutting Speed : 250m/min

1. 100% virgin raw material of powder for each insert to ensure you top and stable quality.

2. High technical production line to ensure delivery on time.

3. More than10,000 sets of of molds with various of types, sizes, chipbreakers and coating for customer to choice to meet customers requirements. Also we accept special design to open new mould according to customers drawings and samples.

4. Different packages :different color /brand/size of inner plastic box and outside wooden box .

5. 24 hours on line for sales and after sales service and in time technology supports.

Specification:

|

|

CCMT09T308 Turning Tool Carbide Inserts Wear Resistance Long Tool Life Images |