| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : Zhuzhou Xinhua

Model Number : TNMG160404-VF

Certification : ISO9001:2008

Place of Origin : China

MOQ : 10pcs

Price : Negotiable

Supply Ability : 400000PCS PER MONTH

Delivery Time : 3-4days

Packaging Details : 10pcs in plastic case,and then packed in a carton.

Material : Tungsten carbide

Workpiece : steel finishing

Holder : turning toolholder/lathe toolholder

Color : Gold

Article number : TNMG160404-VF

Coating : PVD COATING

Hardness : HRA91-93

Application : External Turning

PVD Coated Cermet Inserts TNMG160404-VF Finishing Cutting CNC Machine Turning Tools

Specification:

1. 100% virgin raw material of powder for each insert to ensure you top and stable quality.

2. High technical production line to ensure delivery on time.

3.More than10.000set of of molds with various of types, sizes, chipbreakers and coating for customer to choice to meet customers requirements.

Also we accept special design to open new mould according to customers drawings and samples.

4.Different packages :different color /brand/size of inner plastic box and outside wooden box .

5.24hours on line for sales and after sales service and in time technology supports.

Description:

Cermet Inserts are excellent for all machining applications where specifications for high surface quality, dimensional stability and tight tolerances must be adhered to. They guarantee long tool life with small to medium chip cross sections and uniform allowances, and are ideal for fine finishing, finishing and rough finishing of steel, sintered metal and ductile cast iron.It has a reinforced structure that provides excellent chipping resistance, reducing the wear on the insert and preventing sudden fracture.

Application:

| Material | Material Characteristics |

| Carbon Steel, Alloy Steel and Tool Steel 36-48 HRC: | • Higher carbon content |

| Ferritic, Martensitic, and PH Stainless Steel under 48 HRC | • Brittle |

| Austenitic Stainless Steel: | • Becomes gummy under machining operations due to nickel content |

| Ductile and Malleable Cast Iron | • Very difficult to machine • Small depth of cut • Spherical form graphite makes machining difficult • The carbide concentration creates hard spots • The material structure is not uniform • The crater wear and flank of the insert makes machining difficult • The insert tool life is less than gray cast iron |

| Gray Cast Iron | • Flake form of graphite makes machining easy |

Cermet Inserts Type:

| CCMT060204-MT | DCMT11T308-MT | TNMG160408R/L-F | TPKN1603PDTR |

| CCMT060208-MT | DNMG150404-MT | TNMG160402R/L-2G | TEKN1603PDTR |

| CCMT09T304-MT | DNMG150408-MT | TNMG160404R/L-2G | TEKN2204PDTR |

| CCMT09T308-MT | DNMG150404-FG | TNMG160408R/L-2G | SPKN1203EDTR |

| CCMT09T304-FG | DNMG150408-FG | WNMG080404-MT | SPKN1504EDTR |

| CCMT09T308-FG | DNMG150404-VF | WNMG080408-MT | SPKR1504EDR |

| CNMG120404-MT | DNMG150408-VF | APMT1135 | SPKR1504EDR |

| CNMG120408-MT | TNMG160404-MT | APMT1604 | SEKN1203AFTN |

| CNMG120404-FG | TNMG160408-MT | TPKN110304 | SEKN1203AFTN |

| CNMG120408-FG | TNMG160404-FG | TPKN110308 | SEKN1203 |

| DCMT070204-MT | TNMG160408-FG | TPKN160304 | SEKR1203AFTN |

| DCMT070208-MT | TNMG160402R/L-F | TPKN160308 | SEKR1504AFTR |

| DCMT11T304-MT | TNMG160404R/L-F | TPKN1603PDER | SNKN1204ANTN |

Carbide turning inserts specifications :

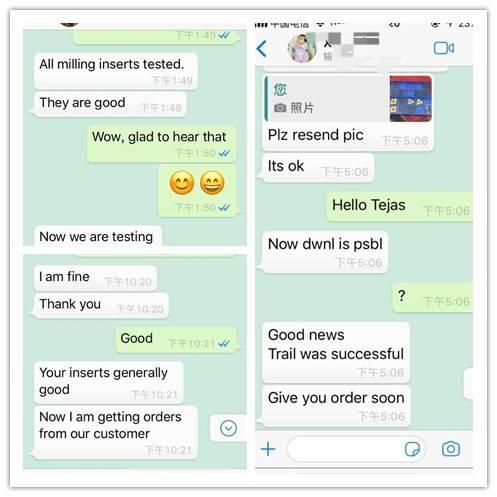

Customers Feedback:

|

|

PVD Coated Cermet Inserts TNMG160404-VF Finishing Cutting CNC Machine Turning Tools Images |